Infrastructure

Infrastructure

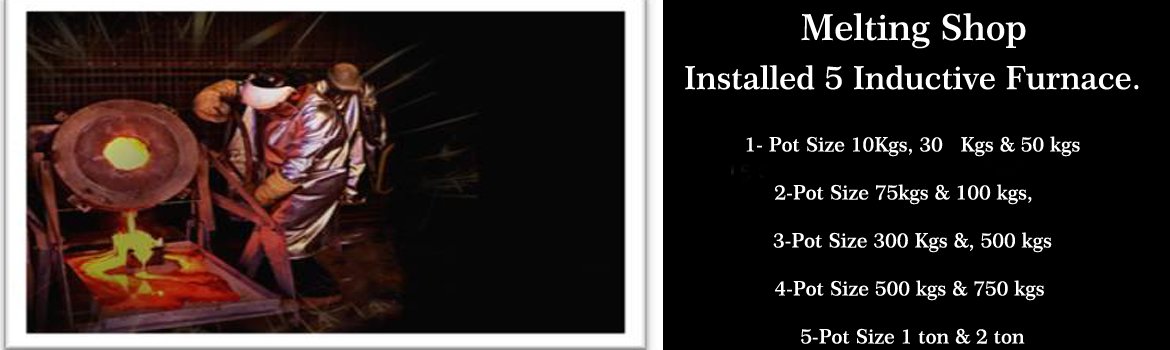

We have 5 different induction furnaces. We have installed capacity 10387 ton in Ferrous and Non Ferrous casting. We defined different pots for different materials. Total Group Factory built up area is 1,60,000 sq/feet. In that following areas are categorized as:

- 20000 sq/feet for Investment casting foundry

- 8000 sq/feet for foam casting foundry

- 4000 sq/feet for Centrifugal casting foundry

- 6000 sq/feet for Sand Casting foundry

- 15000 sq/feet for Machine Shop

- 2000 sq/feet for Inspection facilities

- 1000 sq/feet for Hydro testing

- 1000 sq/feet for Laboratory

- 20000 sq/feet for Fettling department

We have well equipped, Air-Conditioned Waxing Department in that advanced machines are available. Waxing Department is in controlled temperature. We have Auto-Coating Facility in shelling department. Shell soaking in controlled temperature and humidity. We have separate shell stock Room for Customer Just-In-Time delivery.

CENTRIFUGAL CASTINGSSince last 30 years, we are in Ferrous and Non Ferrous centrifugal casting. Also As per Customer Requirement we made Customer Tailor Made grades. Our specialty is making of Vertical and Horizontal Centrifugal Castings. We are making BABBIT METAL BEARING from centrifugal process whose range from 40 mm to 1000 mm in split and round diameter. We are giving Bonding Test as per Standard.

For Horizontal centrifugal range is 40 mm to 1800 mm in Non-Ferrous and in ferrous 40 mm to 1000 mm and length 2 m.We have full Automized Machine for Casting eject and in built mould spray facility.

Vertical centrifugal casting facility also available in Ferrous and Non Ferrous. For making two half die, we have separate tool room. From that we make Worm Wheel, Ball Valve-Ball, Bearing plate, Clyding plate. This is from 60 mm to 1000 mm.

Quality control being of paramount importance, Amruta relies on process designs & control to ensure superior defect free casting with fine grain size & free non-metallic inclusion tanks to stringent quality measures. Amruta Products perform reliably under high temperature & high stresses, level 1 radiographic quality & superior mechanical properties have made Amruta Products popular across all over India as well as abroad.

- MATERIALS:

• Non-ferrous- Gun Metal, Phosphorus Bronze, Lead Bronze, Aluminium, Bronze, Manganese Bronze, Aluminium, Gear Bronze, Bearing Bronze.

• Ferrous- Cobalt Base, Duplex Grade, Stainless Steel SS304, 316,316713162, ca15, Plain Carbon Stills & all alloys. - RANGE:

- Ø 40mm upto 1200mm in Non Ferrous

- & Ø 50mm upto 650mm in Ferrous length 200,300 & 600mm

- Ferras – 50mm to 1000mm & length 2 meter

- Radial allowance Ø & id 12mm each

- Vertical capacity Ø 300mm

- BABBIT METAL BEARING RANGE

- min. 400mm to 850mm in split

- Id 75mm thickness minimum lining 2.5mm to 50mm

- Bonding as per IS standard Bond Test, DP, UT

For Foam Casting, we use Foam Making Machines in that Vertical and Horizontal Machines available in which 1300 mm X 1300 mm tables are formed. These machines are auto-controlled. For that we have separate Foam making process department. We made coating of 1.5m X 1.5m single foam pattern.

We also have automized, eco-friendly Heat Room for removing foam from shell. For pouring we use Vacuum pouring system which is automized, in that near about 1800 mm X1800 mm single piece can pour.